Vintage Radio Journey

radio > journey

Why This Radio Exists

This radio started as an experiment, but it became something much more personal. I wanted to build a music player that felt like the radios I grew up around. You turn a knob. It plays. No apps. No accounts. No wake words. Just sound.

When my dad’s health declined, that simplicity mattered. He didn’t need a smart speaker listening in the corner. He needed something familiar. Something immediate. Something he could understand without instructions.

So I built a radio that does one thing. It turns on and plays music. And when you turn it off, it stops. That constraint became the design.

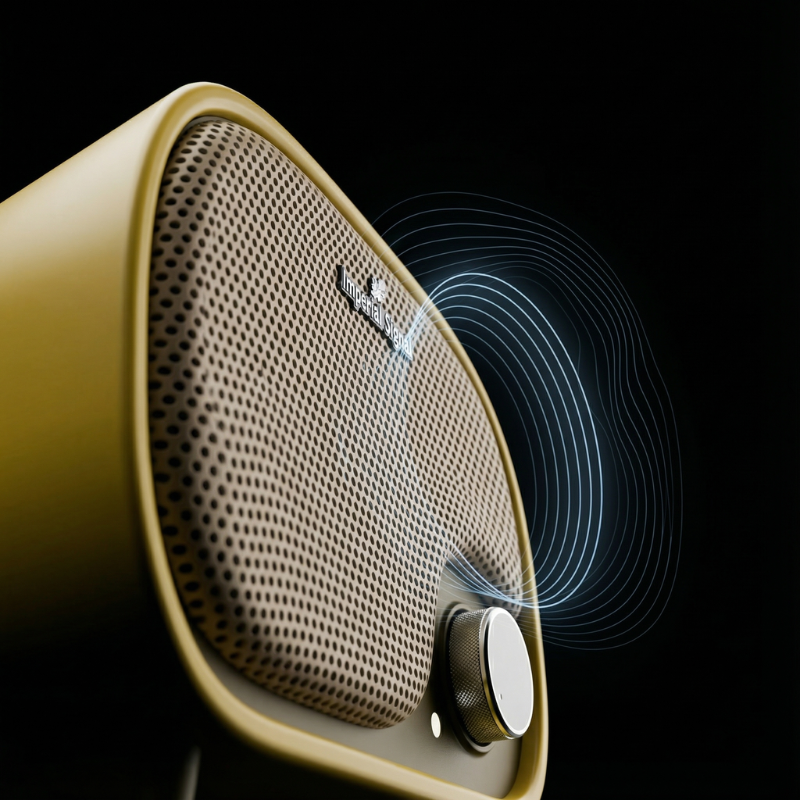

AM Radio Vibe

Mono playback with subtle compression and character. It feels like an old AM radio sitting on a kitchen counter.

Completely Offline

No internet connection. No updates. No tracking. Music lives on an SD card and plays in sequence.

Simple & Tactile

One knob controls power and volume. One button changes tracks. Nothing hidden behind screens or menus.

What started as a simple idea turned into a series of experiments, mistakes, and redesigns. The videos below were released on YouTube (probably what brought you here) that tell the story best about how I got here.

The First Launch

It started with a simple question: what if a modern music player could feel like an old tabletop radio? Not a screen. Not an app. Just something you turn on and it plays. In this first build, I designed a vintage-style shell around a Raspberry Pi and a tiny MP3 player, controlled by a single volume knob and one button. USB-C power. Simple wiring. Pre-loaded music. Along the way I had to learn circuitry, soldering, and programming from scratch. The moment it all clicked was when I added a custom audio file that mimics the sound of an AM radio tuning in. That tiny detail made the whole thing feel alive.

Built for My Dad

This is where the project became personal. I set out to design a simple, offline music player inspired by old tabletop radios. One knob. One button. No wake words. No screens. I built it for my dad as he was living with dementia and cancer, so he could just turn it on and listen. I gave it to him for Christmas. He passed away seven days later. After sharing the story, people began asking how they could build one for their own families. That moment shifted everything. What started as a personal experiment became an open, community driven project with tutorials, files, new shell designs, printed knobs, lower cost parts, and a growing group of builders carrying it forward.

Rethinking the Grill

By the third chapter, the radio was working, but one part kept bothering me. The grill took seven hours to print and required a mountain of supports. It worked, but it felt inefficient. So I started experimenting with thermoforming, printing the grill flat, heating it, and bending it over a mold to save time and material. The first attempts technically worked, but the strain distorted the holes and stretched the pattern in ways I didn’t like. That led to a deeper dive into infill density and pattern, not just for strength but as a design tool. I tested geometric infill, adjusted densities, and built a mold and ring press to gently shape the grill into place. This video captures that phase of experimentation, where frustration turned into refinement and the design became smarter, lighter, and more intentional.

Thermoforming in Water

After experimenting with heat guns and molds, I tried something different. Hydro-thermoforming. Instead of blasting the plastic with air, I submerged it in 70° C water and bent it over a mold. Tap water wasn’t hot enough, so the stove became part of the process, along with heat resistant gloves and a lot of patience. The first attempts failed when the rim softened and shifted out of place. But after refining the model and dialing in the technique, the results were surprisingly clean. This phase pushed the design further, proving that even the grill could be formed faster and more efficiently with the right approach.

Support the Project?

This project exists because of hours of testing, failed prints, redesigns, and revisions. If you’ve found it useful and want to support future mounts, PCBs, and new designs, you can contribute here. Every spool helps! 🥰

🧵 Buy Me Some FilamentLet's Stay Connected

This project is evolving. When I release new mounts, updated files, PCB revisions, hardware improvements, firmware changes, or entirely new designs, you’ll hear about it first. I’ll also share builder showcases and practical updates that make the radio easier and better to build. No noise. Just relevant information for people actually working on the project. You can unsubscribe anytime.